Pinpoint the location of leaks in 30 seconds or less, helping you avoid costly recalls, protect your brand reputation, and ensure every package arrives safe and sealed.

Whether you’re dealing with leaks right now or warding them off for the future, you’re in the right place.

While other methods only tell you if there’s a leak, our technology shows you where it’s coming from—making it faster and easier to fix the problem and keep production on track.

Tests can be completed in 30 seconds or less, ensuring your production line runs smoothly and efficiently.

25+ years of industry experience and 24 hour response time. We’re here to help every step of the way.

Leak detector works great. No issues and excellent company to deal with.

Leak tester works great and this will save me hours of time every week. Ultimately I’ll be able to turn this over to our hourly workforce. Thanks again for a great product!

We have a tank purchased in 2013 and it's still going with no end in sight, used every day. It’s a solid product and has become an essential part of our quality system.

FlexPak has an outstanding product, pure and simple. It is fast, easy to clean, and very reliable in its feedback. I’m so glad we made this choice; we are able to make small adjustments on the fly to our packaging equipment because of its precise accuracy. 5 Stars for FlexPak!

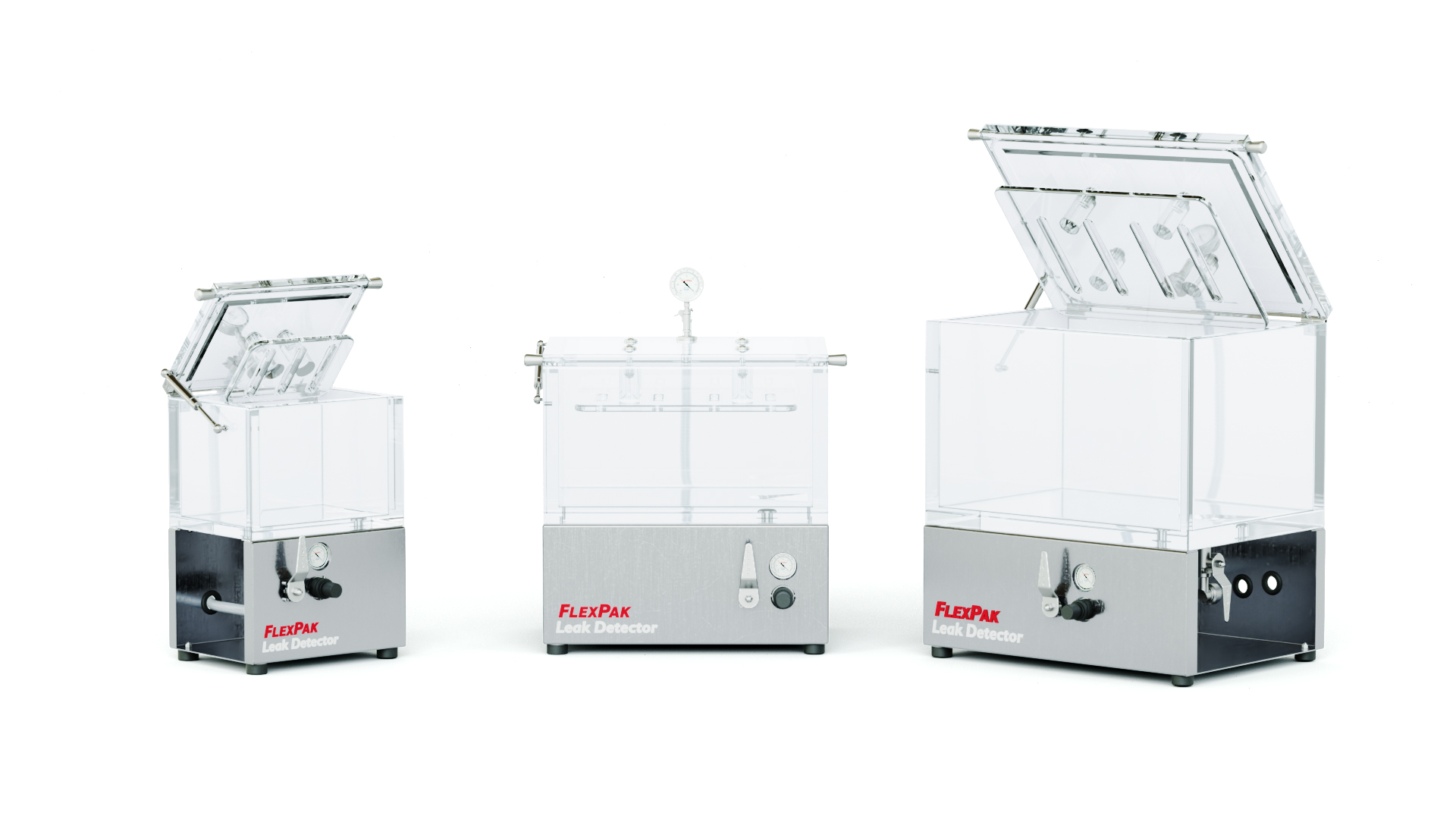

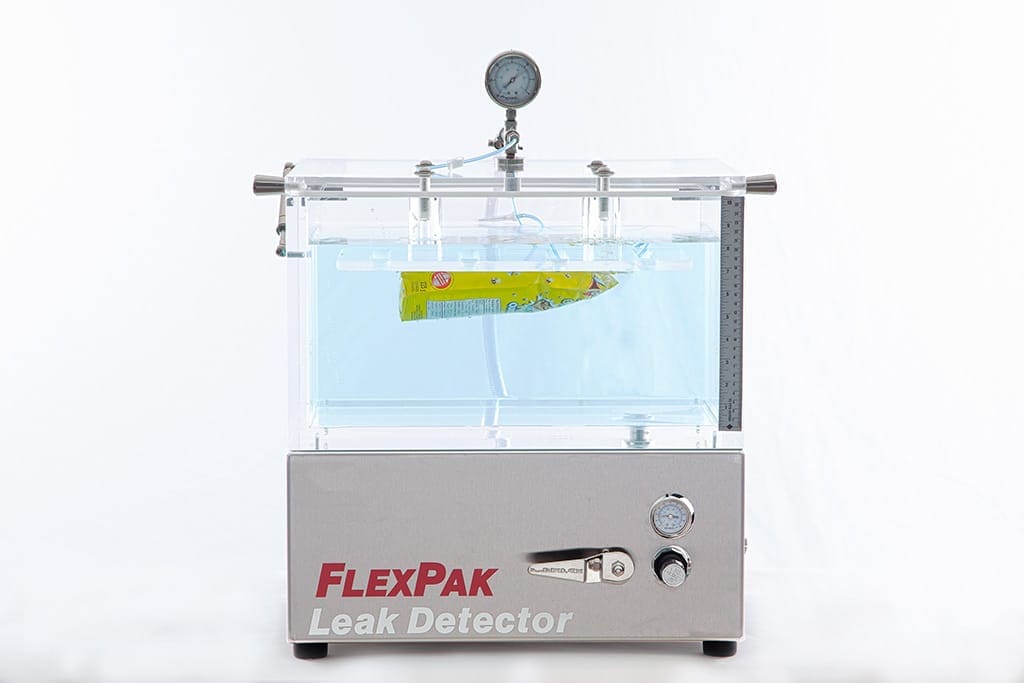

Our Leak Detectors offer reliable, efficient testing in various sizes. If you need more control or ASTM compliance, add an automatic controller or attachment—flexible upgrades, no overhauls needed.

Experience the FlexPak Advantage with our simple 3-step process: our experts work with you to determine the right equipment size and testing protocols for your needs, and then select the appropriate add-ons to ensure your packages reach their destination fully sealed and intact.

Share your package dimensions and the number of packages you’d like to test at once, and we’ll recommend the ideal FlexPak unit.

Get expert guidance to choose the right test for your packaging—Bubble Emission, Altitude Simulation, or other ASTM standards.

We’ll help you select the appropriate attachments and add-ons to configure our Leak Detectors to best suit your Package and/or container testing requirements.

We know your packages go through a lot before reaching their final destination. The FlexPak Leak Detector makes it easy to perform a variety of ASTM package testing methods, helping you to ensure your package’s seals meet your standards.

FlexPak has proudly been providing peace of mind around the globe for over a decade. Customers in nearly every manufacturing industry have come to rely on their FlexPak Leak Detectors, and we’re honored to hold that responsibility. With a wide range of product solutions and a dedicated support team, we’re confident we’ll have a solution that fits your needs.

Please fill out the form below to download our brochure.

"*" indicates required fields