FlexPak has an outstanding product!

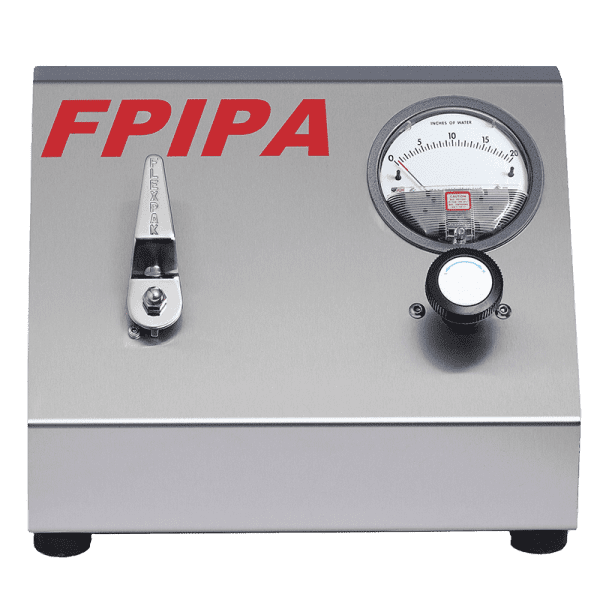

FlexPak has an outstanding product, pure and simple. It is fast, easy to clean, and very reliable in its feedback. I’m so glad we made this choice; we are able to make small adjustments on the fly to our packaging equipment because of its precise accuracy. 5 Stars for FlexPak!