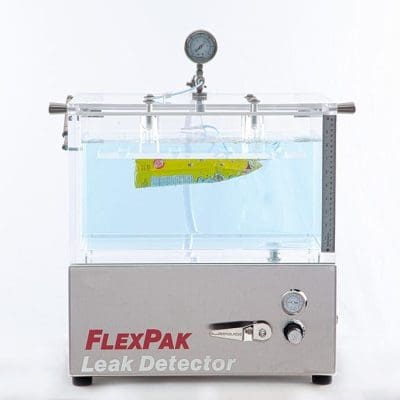

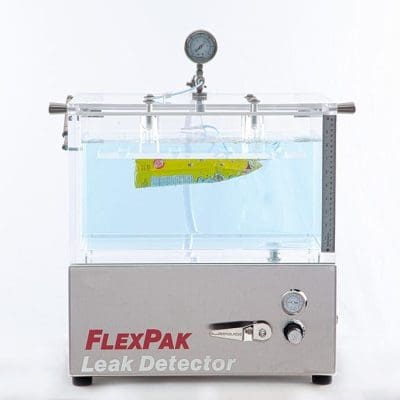

The Bubble Emission Test (ASTM D3078) is the most common test performed on both flexible and rigid packaging. This test can be used to quickly identify leaks in your package.

Altitude Simulation Testing (ASTM D6653) can be used to simulate the stresses a package would experience due to altitude changes during air transit or truck transit through mountain ranges.

Internal Pressurization Testing (ASTM F2096) can be used on packages with little headspace (i.e vacuum-sealed packages) to visually determine leak points.

Dry chamber tests are tests that are performed without water in the Leak Detector tank. The Dry Tank Leak Procedure is best suited for packages whose contents are liquid and have little headspace or air within the package. This test method is typically performed with liquid-filled products (i.e. condiment sachets or bottles with lug-style and threaded caps).

The FlexPak VAC attachment can be used to modify a low-headspace or vacuum sealed package’s internal environment by adding excess air. This is required to perform ASTM testing standards on low-headspace packages.

The Bubble Emission Test (ASTM D3078) is the most common test performed on both flexible and rigid packaging. This test can be used to quickly identify leaks in your package.

Altitude Simulation Testing (ASTM D6653) can be used to simulate the stresses a package would experience due to altitude changes during air transit or truck transit through mountain ranges.

Internal Pressurization Testing (ASTM F2096) can be used on packages with little headspace (i.e vacuum-sealed packages) to visually determine leak points.

Dry chamber tests are tests that are performed without water in the Leak Detector tank. The Dry Tank Leak Procedure is best suited for packages whose contents are liquid and have little headspace or air within the package. This test method is typically performed with liquid-filled products (i.e. condiment sachets or bottles with lug-style and threaded caps).

The FlexPak VAC attachment can be used to modify a low-headspace or vacuum sealed package’s internal environment by adding excess air. This is required to perform ASTM testing standards on low-headspace packages.