Electric Vacuum Pump

We recognize that operating a standard, compressed air Leak Detector isn’t always feasible. The Electric Vacuum Pump makes it simple to perform robust tests when compressed air isn’t available.

Our technology gives you the confidence that your package is reaching its destination fully sealed and intact. Whether you operate in food and beverage, medical and pharmaceutical, or anything in between, FlexPak has a solution for you.

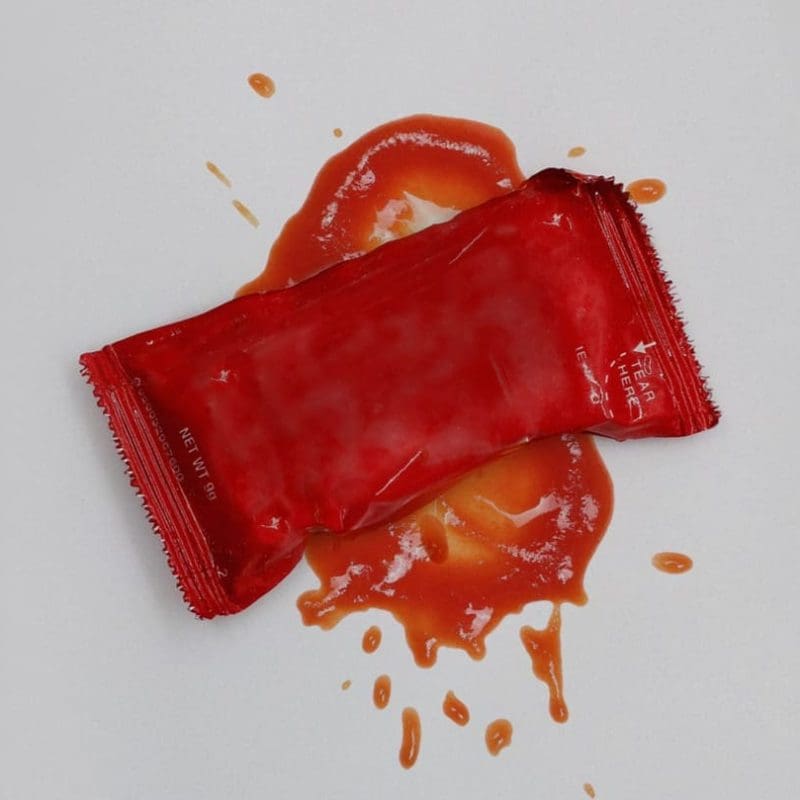

Whether you are looking to test 1 oz sterile sachets or a 10 Kg bag of pet food, we offer various Leak Detectors to suit packages of any size.

38 x 21 x 17 inches (965 x 533 x 431 mm)

31 x 25 x 16 inches (790 x 630 x 380 mm)

29 x 19 x 12 inches (740 x 480 x 300 mm)

23 x 19 x 12 inches (580 x 480 x 300 mm)

19 x 13 x 10 inches (480 x 330 x 250 mm)

17 x 11 x 7 inches (430 x 280 x 180 mm)

10 x 7 x 5 inches (250 x 180 x 130 mm)

38 x 21 x 17 inches (965 x 533 x 431 mm)

31 x 25 x 16 inches (790 x 630 x 380 mm)

29 x 19 x 12 inches (740 x 480 x 300 mm)

23 x 19 x 12 inches (580 x 480 x 300 mm)

19 x 13 x 10 inches (480 x 330 x 250 mm)

17 x 11 x 7 inches (430 x 280 x 180 mm)

10 x 7 x 5 inches (250 x 180 x 130 mm)

38 x 21 x 17 inches (965 x 533 x 431 mm)

31 x 25 x 16 inches (790 x 630 x 380 mm)

29 x 19 x 12 inches (740 x 480 x 300 mm)

23 x 19 x 12 inches (580 x 480 x 300 mm)

19 x 13 x 10 inches (480 x 330 x 250 mm)

17 x 11 x 7 inches (430 x 280 x 180 mm)

10 x 7 x 5 inches (250 x 180 x 130 mm)

360 Degree Vacuum Chamber, capable of performing various Seal Integrity Tests

Choose the best method with your available resources to generate a Vacuum:

Compressed Air

Supply: 75 psig @ 13 SCFM

Vacuum Range: 0-27 inHg (0-90 kPa)

Electric Vacuum Pump Supply: 120/1/60 Or 240/1/60 Vacuum Range: 0-25inHg

Upgrades to NIST certified gauges are available.

Lids require only 5lbs to lift or close. High quality Stainless Gas springs are used to ensure and easy and safe lifting mechanism.

Ensuring your testing equipment is clean can be time consuming. We’ve machined our Testing chambers to ensure minimal hang up points, installed large drains

High-speed drains, easy access corners and all stainless components make washdown and routine maintenance a breeze.

Our Leak Detectors can be used to perform a variety of seal integrity tests to help you determine the source of any leaks in your packaging, ensuring your packaging meets its destination fully intact. Capable of performing seal integrity tests in both wet and dry environments, our Leak Detectors are available in a variety of sizes, and are built to effectively test a myriad of product and package specifications.

Designed to do one thing, identify leaks in packages, our Leak Detectors are built to perform test after test.

The FlexPak design process is focused on delivering robust, long-lasting QA machinery. Our Leak Detectors are easy to operate and use only the highest-quality parts.

Configure your Leak Detector so it is specific to your needs. With various sizes and add-ons available, any package and application can be tested.

A lot of time, energy and costs go into packaging products, and that package has to ensure the product stays fresh, sterile and pristine. We need tools to ensure a package meets its desired performance, and can detect if there are any imperfections in seal quality.

With a FlexPak Leak Detector, packages can be tested to their limits. If there are seal imperfections, a FlexPak will identify the problem. This valuable information allows manufacturers to solve seal integrity issues before they causes a critical failure, compromising your package and product.

FlexPak has an outstanding product, pure and simple. It is fast, easy to clean, and very reliable in its feedback. I’m so glad we made this choice; we are able to make small adjustments on the fly to our packaging equipment because of its precise accuracy. 5 Stars for FlexPak!

We have a tank purchased in 2013 and it's still going with no end in sight, used every day. It’s a solid product and has become an essential part of our quality system.

Leak tester works great and this will save me hours of time every week. Ultimately I’ll be able to turn this over to our hourly workforce. Thanks again for a great product!

Leak detector works great. No issues and excellent company to deal with.

Standard units do not have power requirements, but do require access to compressed air services (see spec. sheet). EVP units require a 120V/240V power supply. All units require a water source for filling the tank, and a means to drain liquid from the Leak Detector after testing. A dedicated water line is not required, as the tank can be filled and drained manually.

Any flexible package, rigid trays, rigid containers, vacuum-sealed packages, and liquid-filled packages (add-ons required). For specific product questions please inquire.